Home Business PR Page

Business PR Page

You'll be surprised at the quality of our finished bored holes and notches! Inquiries to this Company Japanese

Metal Products Manufacturing

KOTANIKOUKAN CO., LTD.

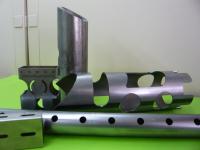

Our company is mainly involved in steel pipe and steel material laser cutting. With our recent introduction of a high-speed 3D laser cutting machine we can now process not only pipes but also angles, flat bars and channels at will. We can design, make prototypes and go into mass production without making expensive dies.

- Traditional pipe boring and notching involves first making a die, and then using presses and drills to finish the work.

Performing this work by hand generates a lot of cost, and a lot of labor is required to clean out the burrs and flash.

Each time the volume being processed increases, it gets harder to meet deliveries.

We resolve all of these problems! Because we use high-speed 3D lasers in our processing no dies are necessary, no burrs or bits of flash are left behind, and the finished products are spectacular. Because of its high-speed capabilities it is suitable for mass production uses.

- (Possible Forms) Square Pipes, Round Pipes, Elliptical Pipes, Deformed Pipes, Ambre, FB, Channel

(Possible Materials): Iron, Stainless Steel, Aluminum

(Processing Range) Round Pipes: 12φ-150φ Square Pipes: Square and rectangular types up to 170mm from the 12 Angle-Opposite Angle

(Maximum Thickness) Iron: 8mm Stainless Steel: 4mm Aluminum: 3mm

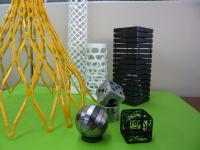

We design on 3DCAD, so multiple hole diameters and non-standard pitches do not pose a problem.

Trust us for all of your complex configuration boring and notching needs.

- -Always Stand with the Customer-

We offer a unified manufacturing platform from prototype to mass production. We are always striving to answer our customer's lot size (small lots), delivery and price needs.

-

Materials Processing Technologies Processing Products and Uses Iron Tubes

Stainless Steel Tubes

Aluminum Tubes3D CAD Design

3D Laser Processing

360 Degree Processing・Sheet Metal Processing, Canning, Bending or Cutting

・Machined, Ground or Polished

・Screw and Hole ProcessingMachine Tools, Automobile Parts, Architectural Hardware, Store Design, Display Products, Steel Furniture

-

Commodity Component Industry Machine Tools Connectors ・Machine Tools Automobiles Connectors ・Automobiles Architectural Hardware Struts ・Architectural Hardware Store Design and Display Products Struts ・Other Products Steel Furniture Struts ・Office Machinery

-

Machine Name Processing Capabilities Number of Machines High-Speed 3D Laser Processing Machine 1 Units High-Speed Fully Automatic Cutter 2 Units Press Cutter 2 Units Circular Cutter 2 Units

- As we design on a 3D CAD system, we can design and build prototypes as needed until the product meets your satisfaction.

Since our equipment is high-speed we can accommodate mass production orders.

We can also accommodate a range of delivery needs. Please feel free to discuss your requirements with us.

| ■ Address | Yao City, Ota Shinmachi 2-50 581-0039, Japan |

|---|---|

| ■ TEL | +81-(0)72-920-1800 |

| ■ FAX | +81-(0)72-920-1801 |

| ■ Representatives | Masahisa Kotani |

| ■ Date of Establishment | |

| ■ Capital | 10,000,000 yen |

| ■ Number of Employees | 15 people |

| ■ Industry | Metal Products Manufacturing |

| ■ URL | http://www.kotani.tv/ |

For more detailed information about our products or offers to act as alocal distributor,please fill out the following form.

Required item

Yao City Charm Creation Department

1-1-1 Honmachi, Yao City, Osaka Prefecture 581-0003 Japan

Click Here to Submit an Inquiry